Quality

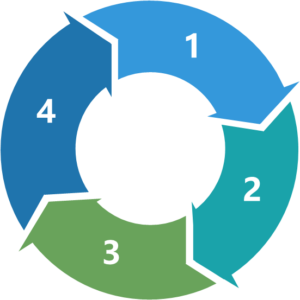

Quality Systems Model

The central goal of quality systems in CLB is to have consistent production of safe and effective products while ensuring that these activities are sustainable. We recognize that a robust quality system will promote process consistency by integrating effective knowledge-building mechanisms into daily operational decisions.

1. Management Responsibility

All managers at CLB demonstrate strong and visible support for the quality system and ensure its implementation throughout the organization.

- Provide Leadership

- Structure the Organization

- Build a Quality System to Meet Requirements

- Establish Policies, Objectives, and Plans

- Review the System

2. Resources

Appropriate allocation of resources is key to creating a robust quality system and complying with the cGMP regulations.

- General Arrangements

- Personnel Development

- Facilities and Equipment

- Control Outsourced Operations

3. Manufacturing Operations

The significant characteristics of the product being manufactured are defined from design to delivery, and control should be exercised over all changes.

- Design, Develop, Document Product and Processes

- Examine Inputs

- Perform and Monitor Operations

- Address Non-conformities

4. Evaluation Activities

Quality systems at CLB continually monitor trends and improve systems by monitoring data and information, identifying and resolving problems, and anticipating and preventing problems.

- Analyze Data for Trends

- Conduct Internal Audits

- Quality Risk Management

- Corrective & Preventive Actions

- Promote Improvement